Color change to needle #9.

Open the Maintenance Menu, then click the Head Timing tab.

Remove the bobbin case, the rotary hook cover, and the needle plate.

Figure 1: AMAYA OS – Maintenance/Head Timing Menu

Head Timing Dial Indicator Gauge and gauge pin (PN: 32453)

#75 (3mm) hex driver or equivalent bent Allen wrench

3lb weight (Melco PN: 32434)

The Z-flag is manually adjusted such that a Bottom Center command initiated either by the keypad or software will generate the lowest possible mechanical position of a corresponding needle at 180° +/-0.5° z-axis position (displayed in the AMAYA Operating System (OS) Maintenance -> Head Timing menu).

Color change to needle #9.

Open the Maintenance Menu, then click the Head Timing tab.

Remove the bobbin case, the rotary hook cover, and the needle plate.

Figure 1: AMAYA OS – Maintenance/Head Timing Menu

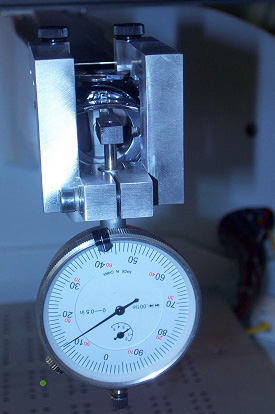

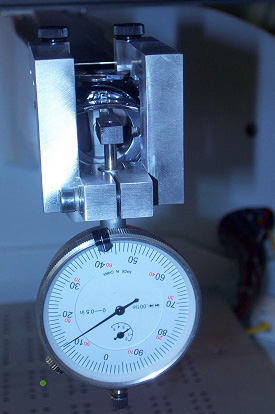

Install the dial indicator (Fixture Number 32453) on the needle plate mounting bracket as shown in Figure 2. Tighten the screws enough to hold the fixture securely.

Figure 2: Dial Indicator Installed on Needle Plate Bracket

Cycle the machine to its Bottom Center position by pressing the Adjustment and Arrow Down keys simultaneously on the keypad (be careful not to let the gauge pin “slam” against the indicator plunger because this may cause damage).

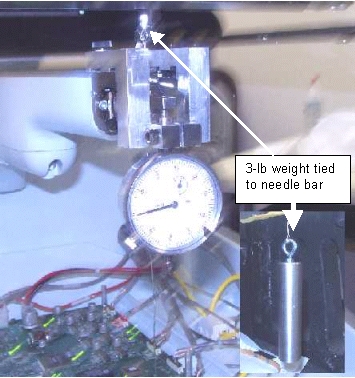

With the indicator plunger in full contact with the needle, hang the 3 lb weight from the needle clamp as shown in Figure 3. Be sure its path is unrestricted and not touching the plunger (contact points will add friction, which will result in inaccurate readings).

Figure 3: Weight Installed

Decrease the angular position by at least 0.004” from the bottom dead center position using the micro-stepping command (Trace and Arrow Down keys).

Increase the angular position until the dial indicator needle stops moving (= “Z Lower Dwell Start”). Continue to increase in angular position; all the while there should be no movement through 179.5° - 180.5°. Increase the angular position to the point where the needle starts to rise (= “Z Lower Dwell Stop”).

Repeat step 6. Then increase the angular position to 180°. If the dial indicator doesn’t read zero, but is within +/- 0.001,” re-zero the dial indicator again. If the dial indicator reads more than +/- 0.001”, go back 3 steps and recheck.

Should there still be movement within the specified range or the dial indicator being off by more than +/-0.001” on the second path, z-timing has to be reset.

Continue to increase the angular position until 0.001” rise (= “Z 0.001” Rise”) is measured. The corresponding angular position at this point should be 182.5+/- 0.5°. If not, z-timing has to be reset.

Color change to needle #9.

Open the Maintenance Menu, then click the Head Timing tab.

Figure 4: AMAYA OS – Maintenance/Head Timing Menu

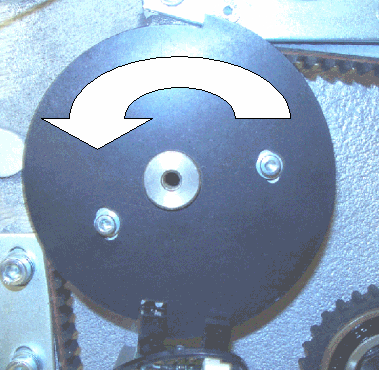

At the rear of the machine, loosen the z-axis flag; and while facing the z-axis flag, rotate it completely counter-clockwise and re-tighten it.

Figure 5: Turn Z-Axis Flag Counter-Clockwise (CCW)

Note: If the machine loses power after this step, it will be necessary to “roughly” reset z-timing. Do so by following the steps outlined below:

a. Shut the machine off.

b. Engage the E-Stop button on the user interface.

c. Turn the machine on and let the system (machine and software) boot up.

d. Manually move the z-axis to its upper most position (upper dead center).

e. Loosen the z-flag at the back of the machine.

f. Rotate the z-flag back and forth to the point where the Z-Index LED is triggered.

g. Tighten the z-flag at this transition point.

h. Reboot the machine.

i. Cycle the machine to Head-Up at least three times by pressing the Adjustment and Arrow Up keys simultaneously on the keypad.

Install the dial indicator (Fixture Number 32453) on the needle plate mounting bracket as shown in Figure 6 below. Tighten the screws enough to hold the fixture securely.

Figure 6: Dial Indicator Installed on Needle Plate Bracket

Cycle the machine to its Bottom Center position by pressing the Adjustment and Arrow Down keys simultaneously on the keypad. (Be careful not to let the gauge pin “slam” against the indicator plunger because this may cause damage)

With the indicator plunger in full contact with the needle, hang the 3 lb weight from the needle clamp as shown in Figure 5 above. Be sure its path is unrestricted and not touching the plunger.

In the Head Timing window, Release Z and manually rotate the z-shaft back and forth as necessary to approximately locate the lowest mechanical position on the dial indicator. The needle will be at it’s lowest point right before it begins to rise.

At this lowest position, Lock Z, then use the micro-step command on the keypad to decrease (press the Trace key and the Arrow Down key) the angular position until the needle begins to rise and continue doing so for 0.003” more.

Using the micro-step command on the keypad, increase (press the Trace key and the Arrow Up key ) the angular position back to the lowest needle position. After the needle stops moving, note the angular position and continue to micro-step in the same direction for at least 1.5° more; the needle should not move.

Verify that the dial indicator is zeroed. If it is not on zero degrees, reset the dial indicator to zero degrees.

Increase the angular position by micro-stepping until the dial indicator registers an increase in position of 0.001”. Record the angular readout at this height and include all decimal places (q).

Important: Add 177.5° to the angle from the previous step (q+177.5) = bz-index setting (include all decimal places). The sum should not be greater than 360°! If it is, then make sure the z-flag was rotated fully counter-clockwise. If it wasn’t, repeat the procedure from step 4 forward.

Using the Step Forward command in the Head Timing tab, increase the angular position by 2° increments until the gauge pin clears the dial indicator plunger. After that, support the weight step upward in 5° increments or more; stopping roughly 5°-7° before reaching the z-index setting position.

At this position, let the weight once again hang freely and use the micro-step command to slowly increase angular position to exactly bz-index setting (Note: It is very important that you don’t overshoot this value. If this happens, rotate back at least 5° before this point and repeat.)

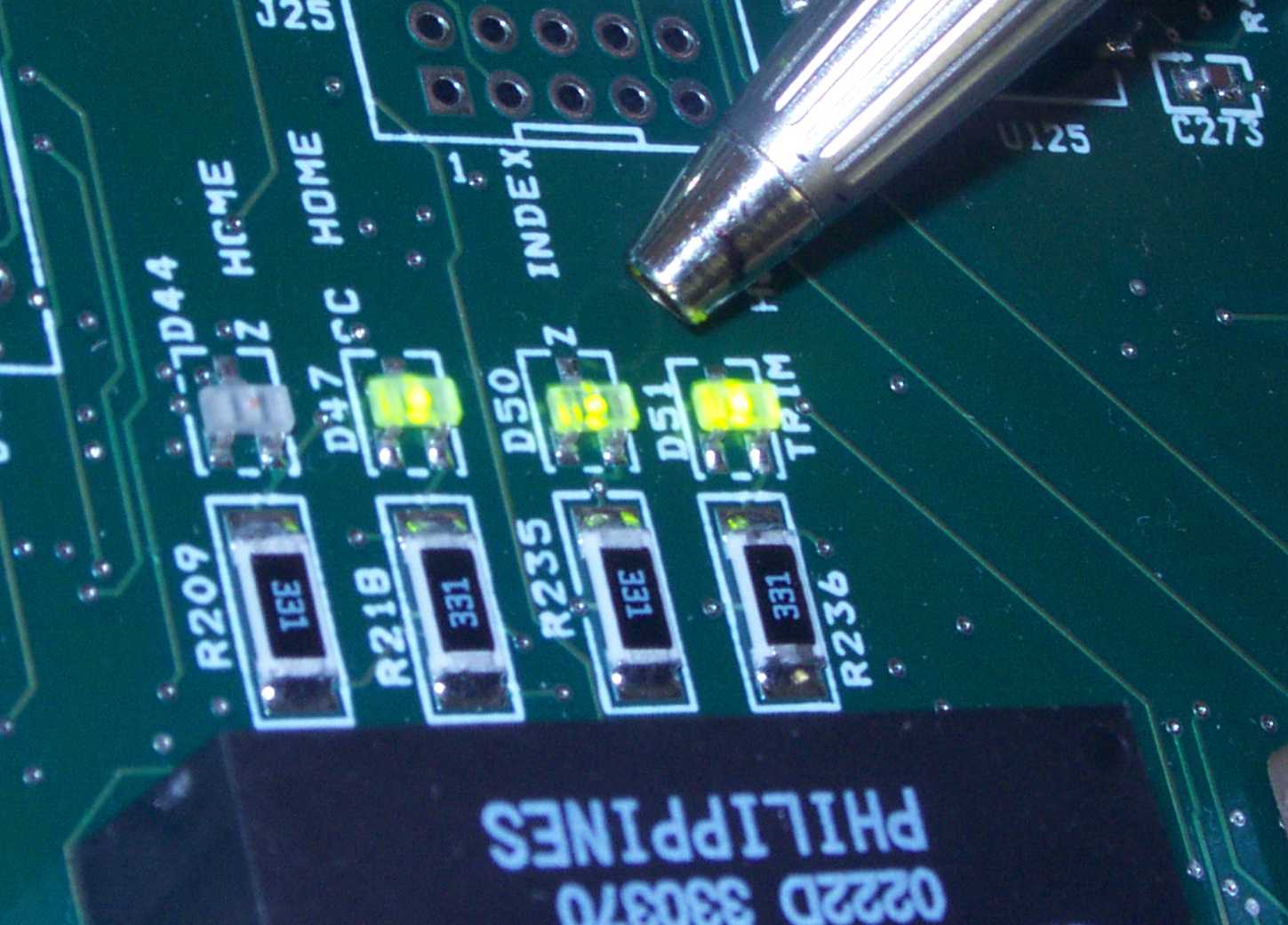

Loosen the z-flag and manually rotate it until the z-index LED (located at D50 on the main PCB as shown in Figure 7 below) changes state.

Figure 7: Z-Index LED (Location D50)

Carefully tighten the flag in place at this transition point with the LED light off. (Note: It is very important that the z-flag is set at a z-shaft angle equal to bz-index setting. The position may change slightly while the z-flag is tightened. If this happens, simply loosen the flag once more, and gently rotate the z-shaft at the rear pulley to re-establish the original angular position and repeat.

The LED must turn off/on at +/- 0.2° of bz-index setting. Use the micro-step command to rotate the z-shaft down in angular position by at least 2°, then forward again and note the angular position at which the z-index LED changes state. Again, this should be within +/- 0.2° of bz-index setting.

Remove the weight and cycle the machine to Head-Up at least 3 consecutive times (be sure the needle in the needle bar clears the dial indicator plunger during this step).

Cycle the machine to its Bottom Center position and replace the weight. (Be careful not to let the gauge pin “slam” against the indicator plunger because this may cause damage).

Decrease the angular position by at least 0.004” from this position.

Increase the angular position until the dial indicator needle stops moving (= “Z Lower Dwell Start”). Continue to increase in angular position all the while there should be no movement through 179.5° - 180.5°.

Increase the angular position to the point where the needle starts to rise (= “Z Lower Dwell Stop”).

Repeat step 21. Then increase the angular position to 180°. If the dial indicator doesn’t read zero, but is within +/- 0.001”, re-zero the dial indicator again. If the dial indicator reads more than +/- 0.001”, go back 3 steps and recheck. Should there still be movement within the specified range or the dial indicator be off by more than +/-0.001” on the second path, z-timing has to be reset.

Continue to increase the angular position until 0.001” rise (= “Z 0.001” Rise”) is measured. The corresponding angular position at this point should be 182.5+/- 0.5°. If not, repeat the procedure from the beginning.

The purpose of this setting is to record the angular position necessary to achieve 0.090” rise from the Bottom Center position. This position will be used for hook timing.

With the weight and dial indicator still in place from the previous step above (0.001” rise), increase the angular position (use 1º steps and the micro-stepping command) until 0.090” rise (= “Z 0.090” Rise”) is measured. Be careful not to overshoot! Record the corresponding angular position (all decimals).

Remove the weight and cycle the machine to Head-Up at least 3 consecutive times (be sure the gauge pin in the needle bar clears the dial indicator plunger during this step).

Cycle the machine to its Bottom Center position and replace the weight. (Be careful not to let the gauge pin “slam” against the indicator plunger because this may cause damage)

Increase the angular position (use 1º steps and the micro-stepping command) until 0.090” rise is measured. Record the corresponding angular position. It should be within +/-0.5° of the position recorded in step 2.

Record the angular position number for the 0.090” Rise position in the lower right corner of the base casting (note all decimals!), crossing the previous number out using a permanent marker.

Remove the weight from the machine.

Cycle the machine to its Head-Up position by pressing the Adjustment and Arrow Up keys on the keypad. Do this at least twice.

Make sure there is proper clearance of the take-up lever gears and the take-up lever guide rails as well as between the take-up lever drive gear and the take-up lever gears to assure smooth operation during color changes. If not, adjust the gear mesh as described in this manual to within the specified limits.