![]()

Hook gap repeatability refers to the hook gap on all of the needles compared to the “closest needle."

Move the needle case to the closest needle (as indicated in the lower right corner of the base casting).

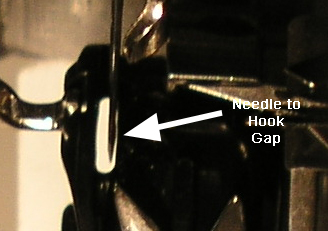

Check and measure the hook gap on the closest needle as shown in Figure 1 below.

Figure 1: Hook Gap Diagram

The hook gap on the closest needle should not be less than 0.004" [0.15 mm] and should not vary more than 0.006” [0.15mm] on the rest of the needles. This gap should be about the thickness of a sheet of paper. The variation in the gaps indicates the front-to-back alignment of the needles in the needle case assembly.

Click on the Head Up button in the AMAYA OS Maintenance-Head Timing menu, color change to needle 1, then click the Bottom Center button and check the hook gap on Needle 1. Repeat this procedure for the remaining needles.

If the hook gap on the closest needle is not correct, you can correct it by adjusting the Needle Guard Gap, following the Hook Timing Adjustment procedure.

If the hook gap repeatability exceeds 0.006” [0.15mm], email QualityAssurance@melco.com for instructions.