![]()

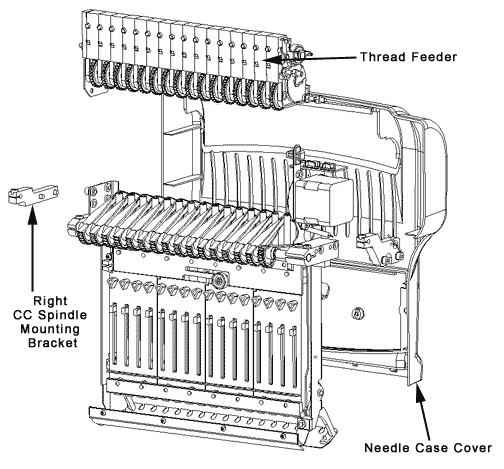

Figure 1 - Needle Case Assembly

Replacement Parts Needed: (for part numbers and description, click on the links)

Thread Feeder Assembly, 16 Needle (comes with hardware installed)

1. Turn the machine off.

2. Remove the needle case access cover.

3. Remove the needle case cover.

Figure 2 - Thread Tubes Connected to Thread Feeder Assembly

4. Remove the thread tubes from the back of the thread feeder.

Figure 3 - Thread Feeder Assembly, Left Bracket

5. Loosen the two nuts on the left side at the end of the long bolts as shown in Figure 3 above.

.

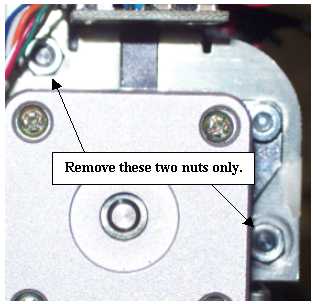

Figure 4 - Thread Feeder Assembly, Right Thread

6. Remove the two socket head screws on the right side as shown in Figure 4 above.

7. Remove the assembly with the 16 thread feeders to the right side as one unit. Do not disassemble the assembly any further.

|

|

IMPORTANT! Do not disassemble the 16 needle thread feeder assembly. Disassembly and reassembly of this component requires specific skills and alignments that are best done at the factory. |

8. Turn the machine on and Color change to needle number 1.

9. Slide the replacement thread feeder assembly onto the needle case.

10. Replace and tighten the two bolts on the right side as shown in Figure 4 above. Tighten the bolts only enough to secure the bracket to the needle case.

12. Install the nuts on the left bracket and tighten them just enough to hold the left bracket in place.

13. Adjust the thread feeder assembly so that the thread feeder gear meshes with the gear on the Color Change, Take-Up Feeder Housing Assembly. See Figure 5. The maximum gap between the gears should be no more than .032" [0.81mm]. Gage Pin (PN: 32996) should not go between the two gears. See Figure 6.

Figure 5 - Thread Feeder Gears

Figure 6 - Gage Pin

13. Click the Thread Feed Home button in the Stepper menu and ensure that the teeth of both gears do not touch. Adjust the position of the thread feeder PCB as required until gear teeth do not touch. Tighten the screws on the right side of the thread feeder assembly.

14. Adjust the bearing on the color change housing so that the red thread feeder clicker for needle #1 is compressed about 50% from the fully extended position. See Figure 7. Make sure the bearing is also centered left to right on the thread feeder clicker.

Figure 7 - Thread Feeder Clicker

15. Color change to needle #16. Repeat step 12 and then tighten the two nuts on the left side of the thread feeder assembly.

16. Color change between needle #1 and needle #16 several times to make sure no clicking noise occurs between the gears. Repeat steps 12-15 if necessary to eliminate any gear clicking noise.