The wide angle cap frame driver, if ordered with a machine, is usually adjusted to the machine already.

Should you receive multiple machines, each driver will be adjusted to one specific machine. The serial number of the machine the driver is adjusted to will be noted on the installation note in the driver box.

If you received notice with your machine that the first time installation and adjustment has already been performed, then proceed to the installation section.

If you did not receive this notice, then you must perform the following adjustment; failure to do so will result in excessive wear to the cap frame driver and reduced embroidery quality.

-

Move the x-carriage all the way back (towards the rear of the machine) using the AMAYA keypad.

(Press the Hoop key  then hold down the Down Arrow key

then hold down the Down Arrow key  ).

).

-

Under the cylinder bed of the AMAYA, locate the cap frame mounting brackets (see Image C below):

Image C

-

Install the driver on the AMAYA: guide the cap driver shaft into the hole in the rear mounting bracket. At the same time, insert the driver dove-tail support bracket into the female dove-tail mounting bracket on the AMAYA.

-

Make sure that both cap support brackets are clearing the needle plate and push the driver further into the rear mounting bracket until it hits a hard-stop.

Image D

-

Tighten the thumb screws on the AMAYA's rear mounting bracket (labeled in Image C) and on the driver male dove-tail bracket (labeled in Image E).

Image E

-

Move the beam forward; position the two thumbscrews located on the rear-mounting bracket over the left and right most inner mounting holes on the carriage and loosely tighten them (start one thumbscrew but do not tighten it all the way before you start the second fastener). The thumbscrews must be screwed in straight (not at an angle) to avoid damage to the inserts in the X-carriage holes. If there is any resistance when tightening either screw, stop, unscrew the thumbscrew and reposition before starting again. After both thumbscrews have both been started in the correct position, tighten them securely with a Phillips screw driver or 6mm Hex wrench (depending on the type of thumbscrews your driver has) to prevent the thumbscrews from coming loose.

Image F

-

Position the driver cap support on the needle plate. Center them front to back and make sure that the raised portion of the needle plate is positioned exactly in-between the two support brackets (see Image D).

-

Move the two support brackets as far down towards the needle plate as possible without them touching the needle plate itself (rule of thumb: leave a gap between the support brackets and the needle plate surface that equals approximately the thickness of a sewing thread).

-

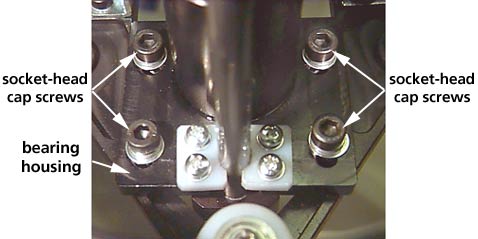

Tighten the bottom left and the upper right socket head cap screw on the driver bearing.

Image G

-

Move the beam with the driver backward and forward. The driver should move without any restrictions.

-

Tighten the remaining two socket head screws on the driver bearing.

Image H

-

Move the driver from the left to the right side. Should a gap between the driver bar and the driver cylinder open up you need to loosen the 3 screws along the interface bracket even more.

-

Move the driver to the center of the carriage (left to right) so that the two red marks on the driver bar and the driver cylinder line up to each other.

Image I