Acti-feed is the feature that replaces the tensioning system on a conventional embroidery machine. It uses thread feed gears, rollers, and a thread sensor bar to feed the appropriate amount of thread for each stitch.

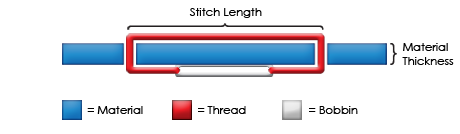

Acti-Feed is the system that calculates and feeds the correct amount of thread per stitch during sewing. The amount of thread feed per stitch is dependent on material thickness

This section will walk you through Acti-Feed settings. Acti-Feed has two modes that can be changed by clicking on the radio button to the left of the desired mode.

- Standard

- Auto

For the initial design, auto should work well.

If using the load design wizard, click the radio button for to complete the load process.

Material Thickness

Material thickness is a determining factor in the amount of thread feed for each stitch. It is displayed under "Acti-Feed" in the Status Tab and the Advanced Status Tab. It can also be found in the Thread Feed Tab.

Material thickness is measured in points. Points are a very fine unit of measure found in the embroidery industry and represent a tenth of a millimeter.

In general, as material to be embroidered increases in thickness, the value for the material thickness should be higher to increase thread feed.

Standard Acti-Feed

In the Status Tab

In the Advanced Status Tab

Standard Acti-feed is used to feed thread at a user specified amount. It will not feed more or less thread than the amount specified.

The amount can be adjusted by clicking on the up or down arrows to the right of the number. The number represents the material thickness.

The default value for the material thickness field is 4 points, but if running in standard acti-feed mode, you will need to adjust it to match your material. It can be adjusted to values ranging from 0-40 points.

Auto Acti-Feed

In the Status Tab

In the Advanced Status Tab

Auto Acti-feed is used to feed thread based on feedback from the thread sensor bar. This allows auto acti-feed to change the material thickness number as it is sewing to reflect changes in the material. This mode is ideal for any material or application that changes thickness. For example, it would be good to use for caps with seams or jackets with appliqué.

While auto mode was designed for materials that change thickness, it works well with most materials. It is recommended for your first sew-outs.

As the product being embroidered changes thickness, the thread dynamic changes and is reflected by the sensor. The sensor sends information back to the software, and the material thickness number is automatically adjusted.

The changes in the material thickness are depicted in the moving graph just below the settings in the advanced tab.

NOTE: Bobbin tension should be set to drop 1-2" when bounced when using Acti-Feed Auto Mode.

Limits for Auto Acti-Feed

Auto acti-feed automatically adjusts for different garment thicknesses. You can however provide a some guidance in the form of lower limits. This will provide a range in which auto acti-feed must operate. Information on these limits can be found in the Acti-Feed Limits section.

The lower limit is helpful when dealing with more delicate or squishy materials. It is helpful were the thread could pull tight, but a little more loft is desired.

Finding the Right Settings

Finding just the right settings or limits for your acti-feed is not always necessary, but it can make a marked improvement in sew quality and machine performace. See details under the Material Thickness section.